Torque Testing

Why Torque Testing Matters in Solar Plants ?

Torque testing in solar plants ensures fasteners are tightened to precise specifications, guaranteeing structural integrity and electrical conductivity. Specialized tools measure rotational force, preventing loosening or failure caused by environmental factors like wind and temperature changes. This process is crucial for minimizing downtime, maximizing energy output, and enhancing safety.

Regular torque testing offers significant benefits, including reduced repair costs, extended plant lifespan, and compliance with warranty requirements. By maintaining secure connections, solar plant owners optimize performance, prevent potential hazards, and ensure long-term reliability. It’s a vital preventative measure that safeguards the investment and ensures consistent energy generation.

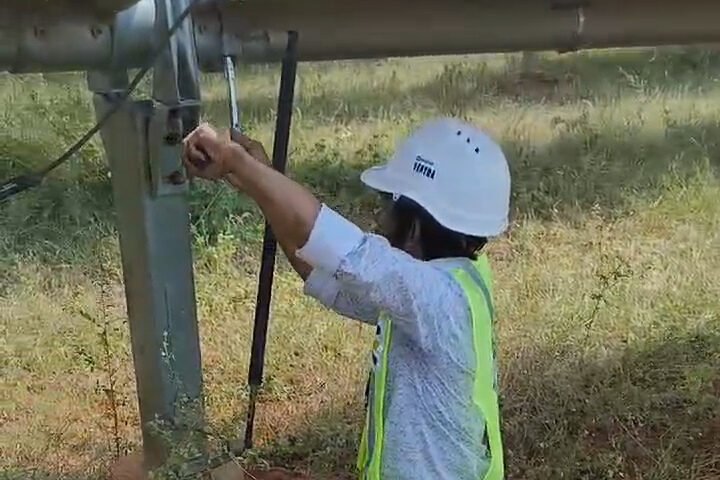

Our Team's Torque Testing Excellence at CleanMax, Tamil Nadu.

Cleanmax , operating its significant 30MW power plant in Tamil Nadu, recently conducted critical torque testing on 60 tables, was carried out by expert inspector, The torque test performed entirely on January 10th, 2025.

The completion of the torque test within a single day demonstrates Cleanmax’s dedication to minimizing downtime and maximizing power output. Our expert inspector, efficient execution of the test, ensuring each of the 60 tables met stringent torque specifications.

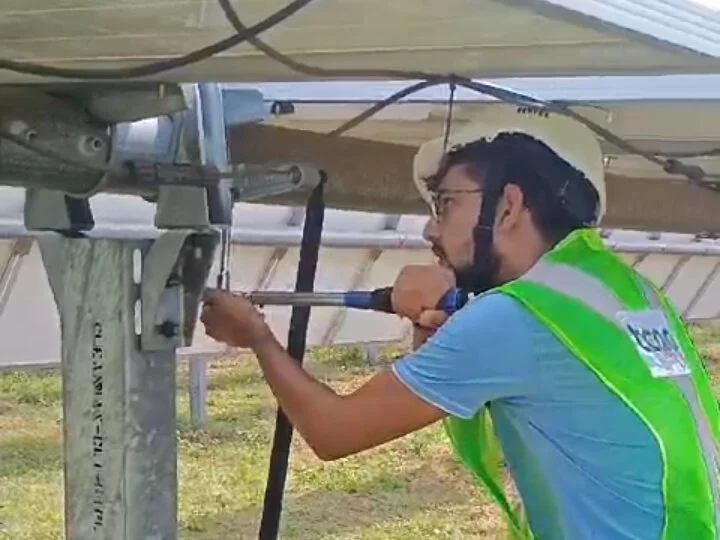

CleanMax's Tight Grip: Torque Testing in Karnataka

Cleanmax’s 48MW power plant in Karnataka underwent a critical torque test to ensure its long-term stability. The inspection, focusing on 300 tables, was conducted by expert inspector. Over four days, from January 4th to 7th, 2025, each table was meticulously checked,

Ensuring all connections met stringent torque specifications. This focused effort was aimed at preventing potential structural issues and maintaining consistent energy production.This thorough inspection highlights Cleanmax’s commitment to reliable, sustainable power